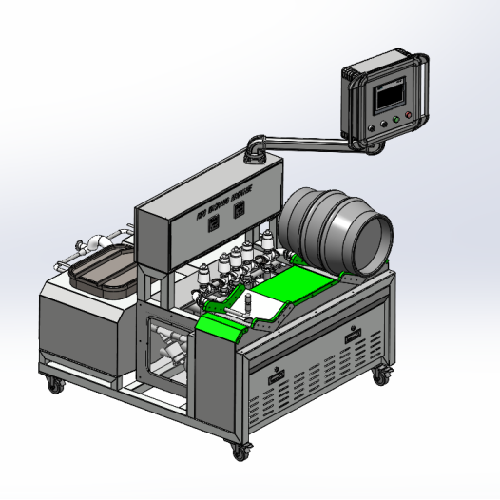

Beer Keg and Machine

Beer Keg Washing Filling Machine

- Product ID:Beer Keg and Machine

- QQ:info@brewdistillequipment.com

- Phone: 0086.15098702311

- Tel: 0086.15098702311

- Email: info@brewdistillequipment.com

- Time: 2023-01-08 09:08:50

- INQUIRY

Shandong Tek Beer Keg Washing Filling Machine

Keg Washer and Filler Technical Parameters

Dimension | 1200*1600*2000mm |

Net Weight | 380KG |

Power | Steam Heating: 3KW Electric Heating: 18KW |

Capacity | 30-40 kegs/H |

Applicable Kegs | Keg with Diameter 250-500mm, Height 360-600mm |

Tank Heating Way | Steam or Electric heating |

Table Board | Fixed or Lifting |

Power Supply | 380V 50HZ or Customized |

Beer Barrel Combined Washing Filling Machine Technical Details by followings

Function and Features

1,Automatic control by PLC, all parameters can be adjusted through touch screen.

2,Cleaning and filling process can be finished in this machine at one time.

3,With unique pressure maintaining system,performance stable and reliable, beer loss minimum.

4,With CIP automatic cleaning system

5.Table board is lifting, and convenient to take kegs, labor-saving and time-saving.

Working Process

Beer Barel Washing process with 2 tanks steam heating

Cylinder pressing→ Air blowing (draining residue) → Water wash (drain)→ Air blowing (drain) → Caustic wash →

Air blowing (caustic recycle) → Hot water wash→ Air blowing (drain) →Hot water wash (drain)→ Air blowing (drain) →

Steam sterilization (drain)→CO2 replace steam (drain)→ Water wash ( hot water recycle)→ Co2 blowing (hot water recycle)→CO2pressurize

Beer Keg Filling Process

Cylinder pressing →Steam blow keg spear (drain)→Drain→Co2 pressurize (evacuate)→

Fill (evacuate)→ Hot water wash keg spear (drain) →Co2 blow (drain) →Drain

Beer Keg Machine Process of CIP

Connect the CIP liquid to the beer inlet→ connect the CIP outlet to the drainage or CIP recycling pipe→ install the blind flange to the filling station→ click "CIP" on touch screen →press "start" on the filling station →press "stop" when finish the CIP.

Note: After CIP process, please connect CO2 to the beer inlet to blow out some residual CIP liquid inside of the beer pipe.

Other Questions, please contact us freely.

E-mail: info@brewdistillequipment.com

WhatsApp: 008615098702311

CATEGORIES

LATEST NEWS

CONTACT US

QQ: info@brewdistillequipment.com

Phone: 0086.15098702311

Tel: 0086.15098702311

Email: info@brewdistillequipment.com

Add: RM 1-1736, Huizhan Intl Gardon, Jinan City, Shandong Pro. China